The Metal Matters 2025 Conference Presented the Full Metal 3D Printing Value Chain and Brought Together Experts from Across Europe

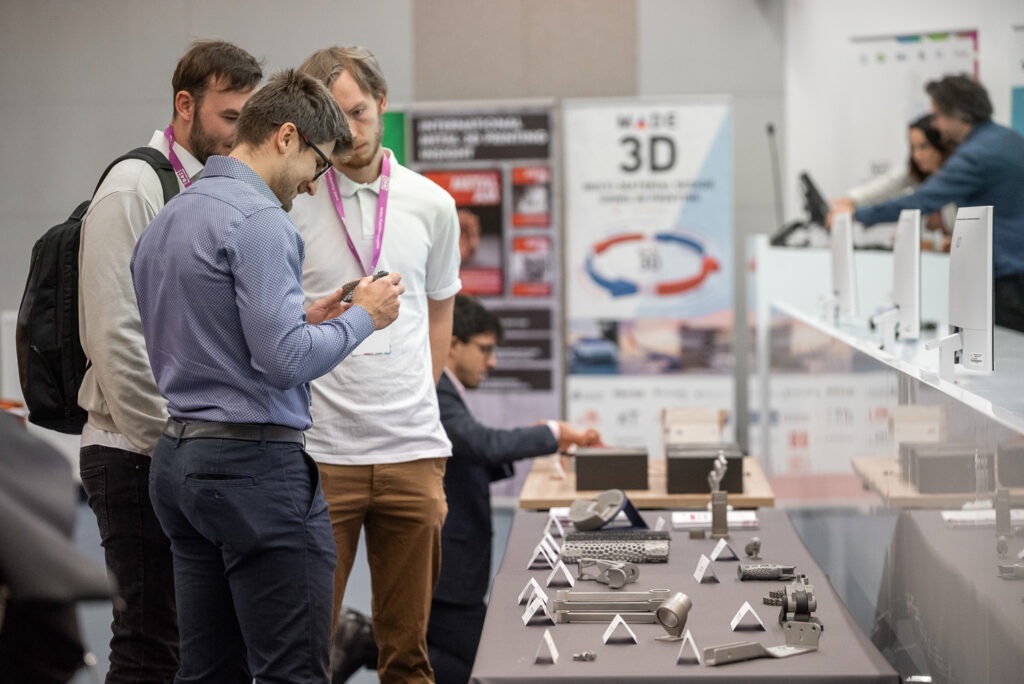

Vestec, Czech Republic – 18 October 2025 – The BIOCEV Conference Centre in Vestec hosted the next annual conference of the Brain4Industry science-industry consortium, this time dedicated to metal additive manufacturing. The event, titled METAL MATTERS – Top Innovations in Metal Additive Manufacturing, was organized by Brain4Industry in cooperation with AMIRES and attracted nearly one hundred experts from industrial companies, research organisations, universities, technology startups and international institutions.

This conference concluded the first three-year phase of the EDIH Brain4Industry project and, for the first time, focused on such a highly specialised topic.

A complete view of the metal AM process in six thematic blocks

The aim of the conference was to present the entire metal additive manufacturing value chain – from materials and component design, through production and post-processing, to deployment in the most demanding industrial sectors. The programme was divided into six thematic blocks, each offering complementary perspectives and a comprehensive overview of key areas.

1. Materials and metal powder recycling

The opening block focused on metal powder quality, alloy development, and—most notably—the recycling of materials, one of the fastest-growing global trends.

Matteo Vanazzi from f3nice (Italy) and Tomáš Čegan from VŠB–TUO presented their findings and demonstrated how to reduce costs and dependency on critical raw materials.

Their insights were complemented by a case study from Zephyra Solabella (NCK MATCA), showcasing the additive manufacturing of spacer grids for UJP Prague—small yet crucial components that hold nuclear fuel rods in place. These parts were produced from extremely demanding materials such as tungsten and zirconium.

2. Design, simulation and automated engineering

International experts Mohammad Uzair and Manuel Ott (Synera, Paderborn University) demonstrated how automated simulations, AI tools and generative design accelerate development, optimise geometry and improve the quality of engineering outcomes.The local CARDAM team, represented by Martin Gášek, expanded the topic with a case study on the development of advanced titanium handlebars for the company KODUZ—lighter, stronger and geometrically more precise than anything achievable with traditional methods.

3. Additive manufacturing process: monitoring, quality and robustness

Eduard Hryha (Chalmers University of Technology) addressed process quality, robustness and productivity in metal AM.

A practical case study was presented by Marek Havel (Brain4Industry), demonstrating the development of a prototype metal heat sink with high thermal conductivity, optimized geometry for efficient heat dissipation, and rapid adaptability thanks to additive manufacturing. This was followed by further development steps carried out for Eaton.

4. Manufacturing processes and Manufacturing-as-a-Service

The fourth block focused on optimising production workflows and post-processing.

Ian O’loughin (Materialise) illustrated how advanced software improves process robustness and productivity, enabling manufacturers to achieve more consistent results.

Ondřej Stránský (HiLASE) then presented a case study featuring advanced laser techniques—laser polishing and laser shock peening. These methods significantly improve surface quality, extend component lifespan and enable post-processing of geometrically complex shapes where conventional methods fail.

5. Industry-specific end-users

This section highlighted real-world industrial adoption.

Oana Alexandra Ciobanu (Safran) shared insights into the deployment of metal AM in aviation—an industry with the highest demands on reliability, precision and certification. She demonstrated how additive manufacturing enables lighter, more efficient and structurally innovative components.

6. Funding technological innovation and collaboration opportunities

The final block, presented by experts from AMIRES, Zabala Innovation, and the Central Bohemian Innovation Centre (SIC), offered an overview of current European funding calls, opportunities for research and innovation projects, and pathways for future collaboration with Brain4Industry.

Ocenění Brain4Industry Awards 2025

As part of the programme, Brain4Industry presented the Brain4Industry Award 2025 to companies that demonstrated exceptional courage and commitment to innovation over the past year.

The award—created in collaboration with the design studio Plastenco—symbolizes the connection between design, technology and industrial cooperation.

This year, the award was presented to representatives of UJP Prague, KODUZ, and Eaton.

Strong attendance, lively discussions and high engagement

The conference received highly positive feedback. Participants particularly appreciated:

- practical case studies,

- clear structure covering the entire AM value chain,

- contributions from international experts,

- and opportunities for cross-sector networking.

Panel discussions often continued into the breaks, and the networking session extended by more than an hour and a half—demonstrating the strong demand in the Czech Republic for a professional platform that connects applied research, industrial expertise and technological innovation.

Amires–Brain4Industry partnership

The conference was made possible thanks to the close collaboration between the Brain4Industry consortium and AMIRES, enabling the combination of European know-how, research insights and industrial needs. This partnership facilitated bringing international speakers and key topics shaping the future of metal component manufacturing to the Czech Republic.

The success of this year’s event confirmed that companies and research institutions are actively seeking a space to share experiences, learn about new technologies and discuss both challenges and opportunities.

Brain4Industry conferences will continue to be an important part of B4I activities in the years ahead.

Contact for media:

Michaela Winklerová

tel: 775 168 722

winklerova@brain4industry.cz